The development of electrified vehicles (EVs) is advancing at a rapid pace due to tightening worldwide emissions regulations and the acceleration of electrification strategies. In the lab, these tests require more driving time to complete as each generation of EVs pushes the boundaries of range. Compared to traditional IC engine vehicles, a different driving automation approach is necessary. One that allows developers to evaluate an EV’s range and help with complex system evaluations for HEVs and PHEVs.

HORIBA is here to help. The new ADS EVO driving robot meets these complex and changing requirements. Its accuracy and reliability over long test periods, high traceability, repeatability, and easy installation make it ideal for the demands of EV testing.

INTRODUCTION

The automotive industry is undergoing a major transformation with new technological trends referred to as Connected, Autonomous, Shared & Services, Electric (CASE). These trends require new development approaches and the optimization of complex systems in the same or shorter time frames. It is also necessary to balance this against the need to comply with stricter environmental regulations and take into consideration the Real Driving Emissions (RDE) test regime. In addition, the investment decisions made today must also factor in future regulatory developments and be future proofed.

ISSUES IN ELECTRIFIED VEHICLE DEVELOPMENT

The development of electrified vehicles is advancing at a rapid pace due to the tightening of worldwide emissions regulations and the acceleration of electrification strategies of various countries and companies. A different approach is needed to evaluate the range of electrified vehicles compared to conventional internal combustion engine vehicles. It requires more vehicle driving time and therefore a solution is needed to maintain high driving accuracy over long periods of time.

The Need for Prolonged Testing

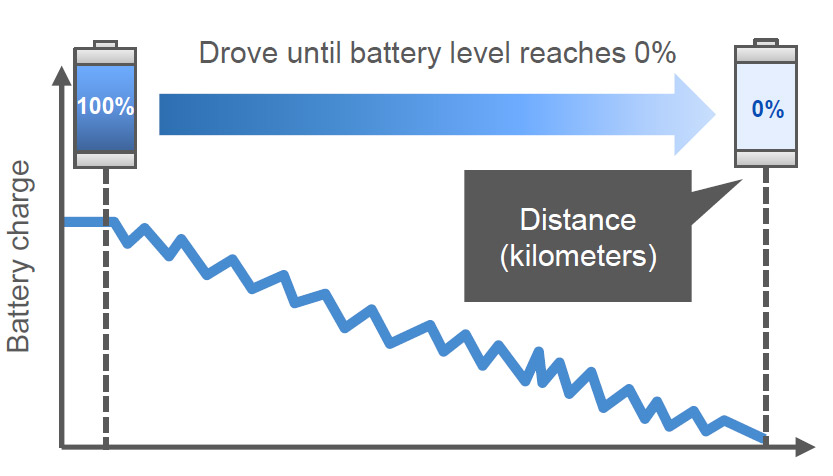

The test procedure to determine the electric energy consumption of pure battery electric vehicles is conducted by charging the vehicle’s batteries to full capacity and then driving the vehicle in a mode specified by regulations multiple times in succession to consume the battery’s energy reserves. The distance traveled until the vehicle is unable to continue operating in this mode is then recorded as the result. Each generation of electric vehicles are pushing the boundaries of vehicle range and this has a knock-on effect on the duration required to fully deplete a battery. This type of testing is resource intensive occupying test laboratories, equipment and personnel. In order to offset some of these challenges, the regulatory authorities have specified a test mode that can be used for the evaluation of vehicle range in a shortened timeframe. But a test with 500 km of range using this mode takes approximately 7 hours (Fig.1, HORIBA calculations).

*Estimated duration time for WLTP-STP cycle driving at HORIBA

Figure 1 – Duration time by electric vehicle range (our calculations)

The Need for Complex Systems Evaluation

Hybrid Electric Vehicles (HEV) and Plug-in Hybrid Electric Vehicles (PHEV) that use both an internal combustion engine and a battery as power sources have large variations in fuel efficiency over specific driving scenarios depending on the strategy employed by the vehicle for a given condition.

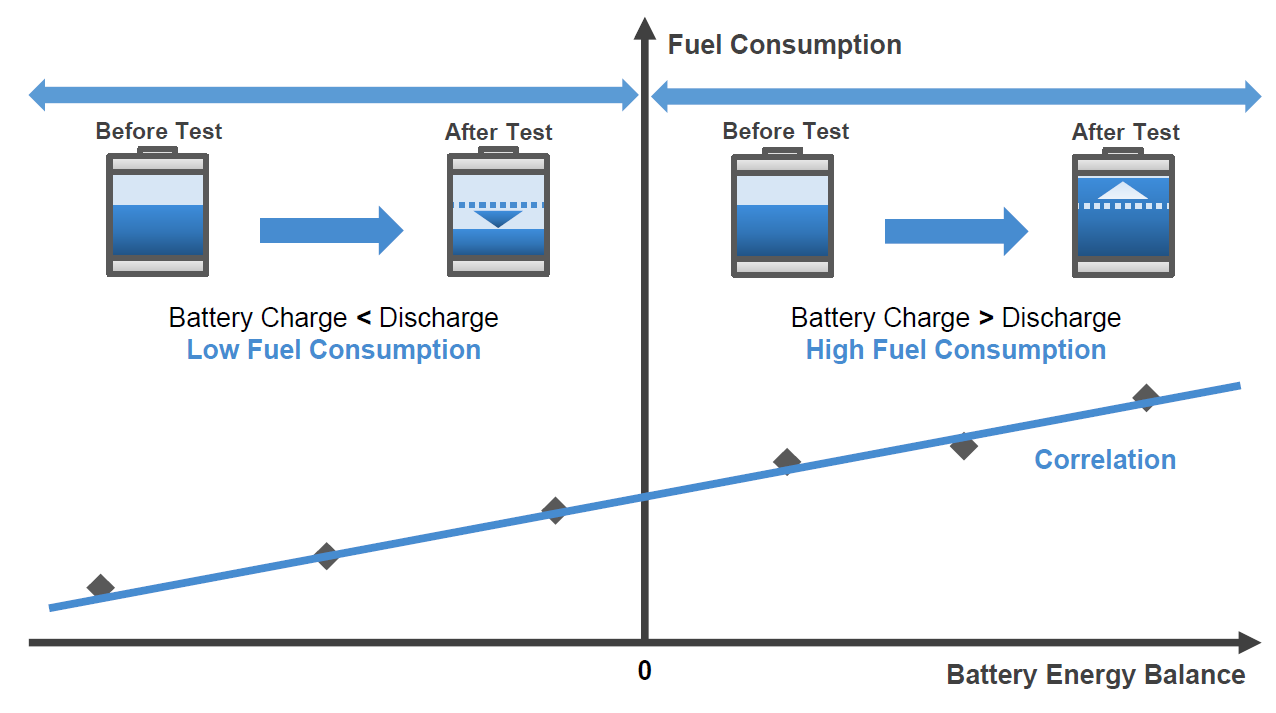

The main variable of the strategy which is how much of the battery’s energy is used during a particular part of a drive sequence (or test cycle, in the case of laboratory testing). For example, if a greater proportion of the test was conducted using the battery’s electricity energy then the result will show a lower fuel consumption than if the vehicle had used more energy provided by the internal combustion engine system (Fig.2). Therefore, it is necessary to examine the correlation between a vehicle’s battery energy balance, the vehicle’s energy strategy and the vehicle’s fuel consumption. In order to do this kind of assessment a huge number of test runs are usually required to be performed to determine the correlation. Furthermore, the correlation is poor if there is variability in the way the vehicle is driven, so a highly reproducible drive with as little variability as possible is desirable.

Figure 2 – Correlation between battery energy balance and fuel consumption

IMPROVING THE EFFECTIVENESS OF VEHICLE DEVELOPMENT WITH THE ADS EVO

The ADS EVO driving robot (Fig.3) supports the automation of vehicle driving for a range of different testing scenarios and produces several benefits which enhances the effectiveness of vehicle product development.

High repeatability and consistency during long tests enable customers to investigate durability issues, monitor the impact of a prolonged operation in a given vehicle mode or complete several tests back to back reducing overall laboratory time.

Its high accuracy combined with its repeatability provides confidence in the test results and reduces the influence of driving inputs. Comparisons can therefore be made more easily between different test regimes, controls strategies and system designs to optimize the final solution. For example hybrid vehicle fuel consumption and energy balance can more easily be correlated. An additional benefit of this is the reduction in the number of tests required which may otherwise be needed to account for variance in driver input.

The ADS EVO can support test laboratory correlation and improve the reproducibility of tests across a customer’s test laboratory network. The self-learning function combined with the ability to save the setup parameters means the ADS EVO robots stationed at other test laboratories can share the same setups and help achieve a high correlation between test facilities across the globe.

In addition, HORIBA has significantly improved the installation of the ADS EVO by reducing the weight of each unit. This improves test laboratory efficiency by allowing quicker vehicle changes and test preparation. It also has a flexible system architecture that allows for additional appendages to tailor the robot to particular vehicles.

Figure 3 – ADS EVO mounted on driver seat

SUMMARY

As vehicle development efforts are rapidly increasing due to the diversification of power sources, stricter environmental regulations, and the increasing complexity of systems, it is important for vehicle manufacturers and related industries to develop vehicles more efficiently. As mentioned, conventional vehicle testing methods are facing various challenges to improve efficiency, such as the increase in duration time and number of tests. The ADS EVO, a driving robot with high traceability, repeatability, and easy installation, solves these problems and contributes to the efficiency of customers’ vehicle development.

![]()

Headquartered in Kyoto, Japan, the HORIBA Group is a global leading supplier of measurement technology and systems for various fields from automotive testing, process and environmental monitoring, in-vitro medical diagnostics, semiconductor manufacturing and metrology to scientific R&D and QC measurements.

HORIBA Ltd.

2 Miyanohigashi Kisshoin Minami-ku Kyoto, Japan

HORIBA Europe GmbH Hans-Mess-Straβe 6

61440 Oberursel Germany

HORIBA Instruments Inc. 5900 Hines Drive

Ann Arbor, MI 48108 USA