Aaron Kappes , Steffen Frei , Sebastian Luz , Prof. Stephan Rinderknecht, Institute for Mechatronic Systems, TU Darmstadt; Institute for power electronics and control of drives, TU Darmstadt

An electric Two-Drive-Powertrain using two electric machines is presented, which allows a highly efficient over all usage. The multi-motor approach achieves a downsizing effect, when one motor is deactivated during moderate driving. The novel features of the powertrain are its electric synchronized dog clutches and its two highly overloadable electric machines, each connected to a two-speed sub transmission providing a total of four different electric speeds. This arrangement enables full torque support during shifting processes. In addition, the waste heat from the inverters and the electric machines is used for heating the transmission oil under cold environmental conditions, thus increasing efficiency. Furthermore, the possibility and advantages of adding an internal combustion engine mechanically linked to both sub transmissions and its realization in a public founded project is addressed.

Introduction

Increasing efficiency is a major target in the development of electric drivetrains. In parallel to established BEVs with one electric motor and a fixed transmission ratio, multi-speed [1, 2] and multi-motor [3, 4, 5] con-cepts are gaining importance. At the IMS of the TU Darmstadt, research is focused on multi-motor and multi-speed drives called TDT („Two-Drive-Transmission“). These electric drives combine high efficiency and performance by using a downsizing effect, according to which a highly utilized electric drive can be operated more efficiently than a large one in its corresponding partial load.

The conceptual benefits of an all-electric concept with two small electric machines with two speeds each, called TDT22, have al-ready been outlined in [6]. Efficiency advantages of up to 8.3% were identified for urban use compared to a benchmark fixed speed BEV. For short and slow driving, there is almost no alternative to a BEV from an ecological point of view. When it comes to long range, [7] stated that it is currently not reasonable to realize high ranges by using larger and heavier batteries. The battery capacity of BEVs ca-pable of reliably reaching distances greater than 500 km increases to more than 100 kWh. A current P2 hybrid concept with optimized energy storage sizes and propulsion machines shows poten-tial to reduce the CO2 footprint from cradle to grave because of its smaller battery. To achieve this, however, it must be charged regularly and driven mainly electrical. In addition, there are user benefits such as rapid refueling e.g., using renewable fuels in the future if an even longer distance is to be covered.

With these potentials in perspective, this paper will focus on the de-velopment of a hybrid version of a TDT22 already mentioned in [8]; a TDT4LR („Two-Drive-Transmission for Long Range“). This concept is based on a DRT (Dedicated Range-Extender Transmission) and is cur-rently being developed and built in the public funded Project DE4LoRa for a dedicated use case.

1. Development

The vehicle being developed in DE4LoRa is designed for a typical German average user and leaves a minimal environmental footprint. According to the “Kraftfahrt-Bundesamt” [9] the 101-110 kW power class contained in 2020 by far the most new-registrations in one of the dis-crete subdivisions. This number was only topped by the open-ended category of more than 151 kW. At the same time, the most frequently registered class was the rather unspecific one of SUVs, closely followed by the C-segment [10]. As the former is not suited for an ecological vehicle, the focus is on the latter. According to a study from the Federal Ministry for Digital and Transport called “Mobility in Germany” sur-veyed in 2017 [11], approx. 80% of passenger car trips covered less than 20 km, with only approx. 30% of the total mileage of a vehicle reached on short distances of less than 20 km in total. Therefore, the develop-ment of the drivetrain was focused on this use case (e.g., daily commute to work and twice a year a long trip on vacation).

A BEV designed for this user profile needs a large and heavy battery, barely using its full capacity. In contrast, the DE4LoRa concept was de-veloped to cover ranges of up to 100 km electric combined with the high efficiency benefits of a TDT22. To reduce complexity, two iden-tical electric machines have been designed, each realizing a continu-ous power of at least 40 kW to enable highly efficient driving with one EM during moderate cycles like the WLTC. Furthermore, they can jointly provide 120 kW peak power for short sporty driving. To enable shifting without interrupting traction even at high accelerations, both electric motors are able to provide 120 kW each for the very short duration of a shifting process. The development of these permanent magnet syn-chronous machine is further described in [12].

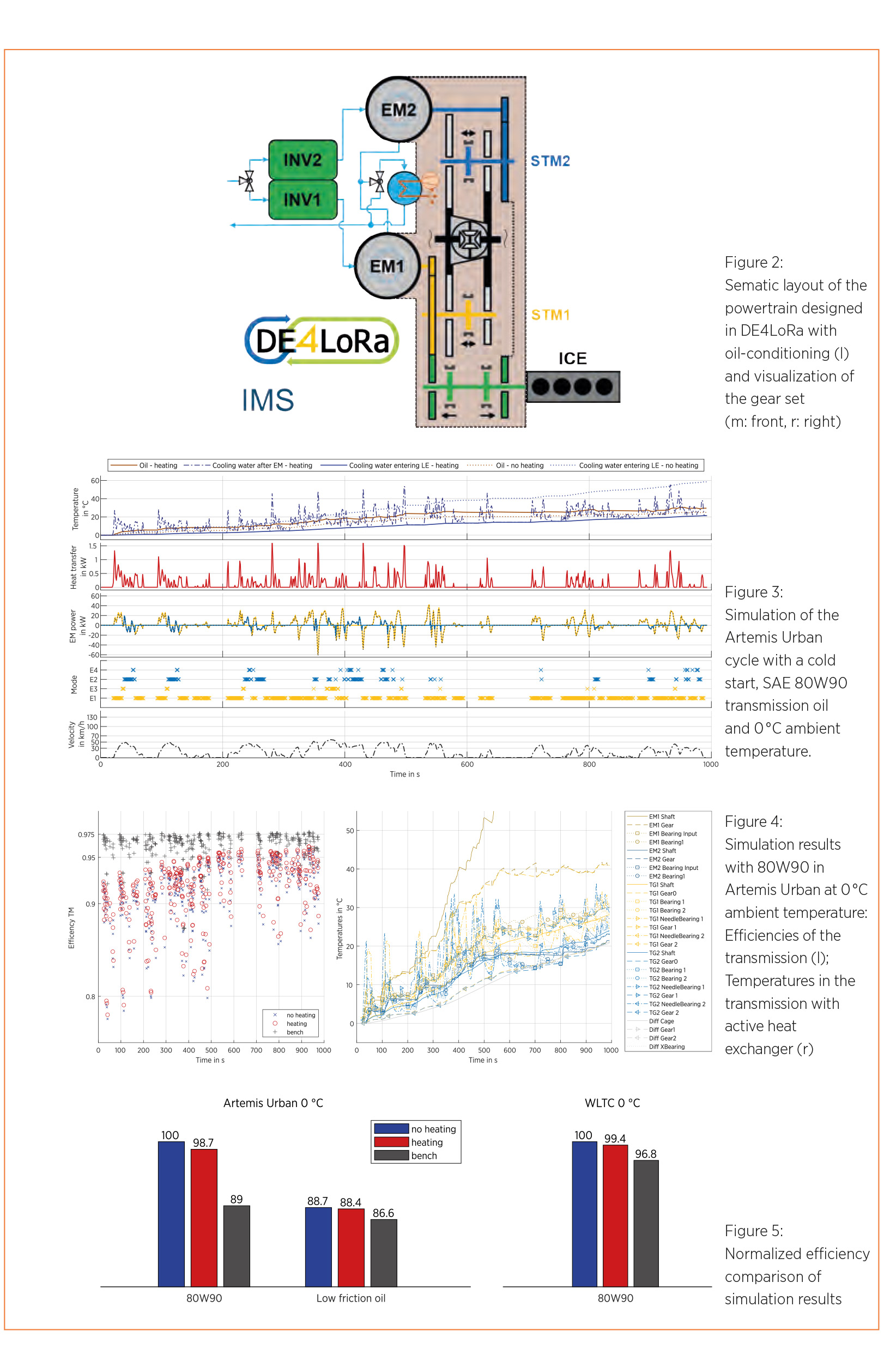

Assuming constant transmission efficiencies, as well as a constant bat-tery voltage and temperatures, a simple heuristic operating strategy for electric modes can be created. The resulting shifting map for this TDT22 is shown in Figure 1. The advantages of four different electric gears com-pared to a non-shiftable transmission are described in more detail in [6].

In an overall assessment of the electric consumption, the relatively low transmission losses cause a significant proportion of the total loss-es due to the high efficiency of power electronics, electric machines, and batteries. Therefore, electrically synchronized dog clutches were chosen to avoid friction losses which would occur in mechanical syn-chronization units. Furthermore, the losses of a transmission increase with higher viscosity of the transmission oil e.g., at low temperatures. To keep the efficiency as high as possible after a frequently expected cold start in winter, it can be beneficial to use the waste heat from the electrical components for conditioning the transmission oil. To further increase electrical efficiency, DE4LoRa also uses a rather high voltage level up to 820 V. Since the efficiency drops with the voltage over the state of charge of a battery, the latter should be kept as high as possible. In this concept, the electrical consumption in the WLTC increases by ap-prox. 5% if started at an SOC of 25% compared to 90%.

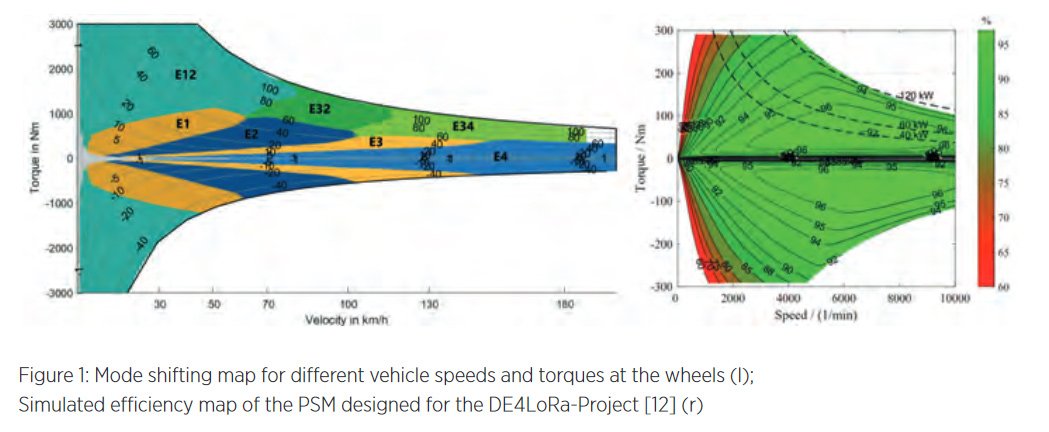

For the use case described above, highly efficient short-range electric driving alone is insufficient. To improve the concept for occasional long-distance, a monovalent methane gas engine is added. This engine can be connected to both sub-transmissions with different gear ratios, as shown in Figure 2, enabling multiple parallel and serial hybrid modes. This integration combined with the high dynamics and performance of the electric drive allowes the gas motor to be operated in a phlegma-tized manner, thus minimizing emissions and maximizing its efficiency.

In addition, methane provides a high energy density per carbon atom, can be produced synthetically more efficiently than liquid synthetic fuels, and, unlike hydrogen, is easy to store and benefits from an existing infrastruc-ture. Optimizing the gear ratios of this transmission involves a compro-mise between highly efficient electric and SOC-neutral hybrid modes, with SOC-neutral consumption being more sensitive to changes. It has been shown that an electric overdrive provides efficiency benefits, re-sulting in a top speed of 180 km/h in SOC-neutral operation in the third, not fourth gear.

2. Oil-Conditioning

During optimization constant transmission efficiencies were assumed between 96.9 and 97.8% for each mode-dependent combination of two spur gears. In real applications, these effi-ciencies depend not only on the acting speeds and torques but also on the viscosity of the gear oil and thus its temperature. With lower temperatures, the transmission losses increase disproportionately. The inverter and electric machine generate usually unused waste heat. If the lubrication concept of the transmis-sion already uses an oil pump, the heat can be used for conditioning the oil by adding a heat exchanger.

The potential depends on several parameters like the current efficien-cies, the water flow rate, and the oil used. To investigate the possibili-ties for this project, an analytical transmission loss model was created, which includes the viscosity of the gear oil in its calculations of churning losses, meshing losses, sealing losses, and bearing losses. Not only the load-carrying elements but also all co-rotating parts for every mode are considered. This model is supplemented by a lumped-element thermal model of all transmission components. All loss effected transmission parts as well as a water-oil heat exchanger and 30% of the losses of the electric machine at the input shafts are implemented as heat sources. Thus, both the self-heating of the gearbox and the heat transfer from an external water circuit is represented.

Two different transmission oils and two different scenarios were consid-ered, using only modes with one EM for simplification. First, a common rather more viscous transmission oil was modeled corresponding to a SAE 80W90. Figures 3 and 4 show the simulation results for a cold start in the Artemis Urban cycle with 0°C ambient temperature.

The efficiency changes of the transmission are shown in Figure 4; in blue without using the heat exchanger, in red with a water flow rate of 1 l/min. In addition, the efficiency with an oil temperature of 60°C at the beginning is shown as a benchmark in gray. Figure 5 shows the most relevant results of the simulations. The heat exchanger in this configuration enables an efficiency advantage of 1.3% which is no-ticeable, but significantly lower than the efficiency with already warm oil. If the gear layout and the acting surface pressures allow the use of an oil with (very) low viscosity, much higher total savings are pos-sible. On the other hand, the benefits of conditioning are hardly notice-able with this lubricant. Finally, the potential in a WLTC at 20°C ambi-ent temperature is evaluated, whereby the heat exchanger leads to an 0.6% lower energy consumption. Prospectively, the usage of additional waste heat by other consumers, such as an internal combustion engine, could achieve greater improvements. Furthermore, the effect could be improved by further optimizing the flow rates and quantity of water and oil.

Conclusion

The concept idea for a hybrid TDT22, the development process as well as the results achieved in the DE4LoRa project so far were stated. It is tailored to fulfill the requirements of an average Ger-man driver with minimized ecological footprint. It covers short distances in highly efficient elec-tric driving due to the advantages of four speeds, uses a comparatively small and thus light battery, a high voltage level, and supplementary oil conditioning. To maximize efficiency, it is rec-ommended to keep the SOC as high as possible. In addition, the effect of transmission oil con-ditioning was examined in more detail, and in summary, the loss reduction potential depends primarily on the oil used. If a conventional trans-mission oil is used, there can be considerable efficiency benefits for short trips and cold am-bient temperatures – 1.3% in this example. How-ever, if the design or maintenance strategy al-lows using a low-viscosity oil, the effect if an oil conditioning decreases significantly and com-bined with longer driving distances and higher ambient temperatures, becomes unnoticeable small.

Gratification We want to thank Max Clauer, Zhihong Liu, and Arved Eßer for theirhelpful feedback and advice.References[1] Biermann, T, “The Innovative Schaeffler Modular E-Axle“, April 2018, Schaeffler Symposium[2] Schmidt, C., Dhejne H., Vallant, W.,

„AVL Two-speed e-Axle – High Efficient and Shiftable Under Load”, November 2021, CTI Symposium, Berlin[3] Xu X., Liang J., Hao Q., Dong, P, et al., “A Novel Electric Dual Motor Transmission for Heavy Commercial Vehicles”, Januar 2021, Automotive Innovation, Springer[4] Hirano, K., Hara, T., “Development of dual motor multi-mode e-axle”, November 2021, CTI Symposium, Berlin[5] Brückner, U., Strop, M., Zimmer, D., „Mehrmotorenantriebssys-teme – intelligente Betriebsstrategie“, May 2017, Antriebstechnik[6] Eßer, A., Mölleney, J., Rinderknecht, S., „Potentials to reduce the Energy Consumption of Electric Vehicles in Urban Traffic”, Juli 2022, VDI Dritev, Baden-Baden[7] Eßer, A., “Realfahrtbasierte Bewertung des ökologischen Potentials von Fahrzugantriebskonzepten“, 2021, Shaker[8] Langhammer, F., Kappes, A., Viehmann, A., Rinderknecht, S., „Novel “Two-Drive-Transmission for Long-Range” Powertrain: Ecology and Efficiency meet Driving Comfort”, October 2021, VDI Dritev, Bonn[9] Kraftfahrt-Bundesamt, „Fahrzeugzulassungen (FZ) Neuzulassungen von Personenkraftwagen und Krafträdern nach Motorisierung Jahr 2020“ – FZ 22; https://www.kba.de/SharedDocs/Downloads/DE/Statistik/Fahrzeuge/FZ22/fz22_2020.pdf?__blob=publicationFile&v=5 last checked: 11-10-2022[10] Kraftfahrt-Bundesamt, „Neuzulassungen von Personenkraftwagen nach Segmenten und Modellreihen“ – FZ 11; https://www.kba.de/DE/Statistik/Fahrzeuge/Neuzulassungen/Segmente/n_segmente_node.html?yearFilter=2020 last checked: 11-10-2022[11] infas, DLR, IVT und infas 360, “Mobilität in Deutschland – MiD: Ergebnisbericht,” Im Auftrag des BMVi, 2017;http://www.mobilitaet-in-deutschland.de/pdf/MiD2017_Ergebnis-bericht.pdf last checked: 11-10-2022[12] Clauer, M., Binder, A., “Automated Fast Semi-Analytical Calculation Approach for the Holistic Design of a PMSM in a Novel Two-Drive Transmission”, September 2022, ICEM, Valencia