Contribution to further eAxle compactness and higher power density

Makoto NISHIJI, Senior General Manager / Chief Engineer, Driveline CE Department, Automotive Business Unit, JTEKT Corporation

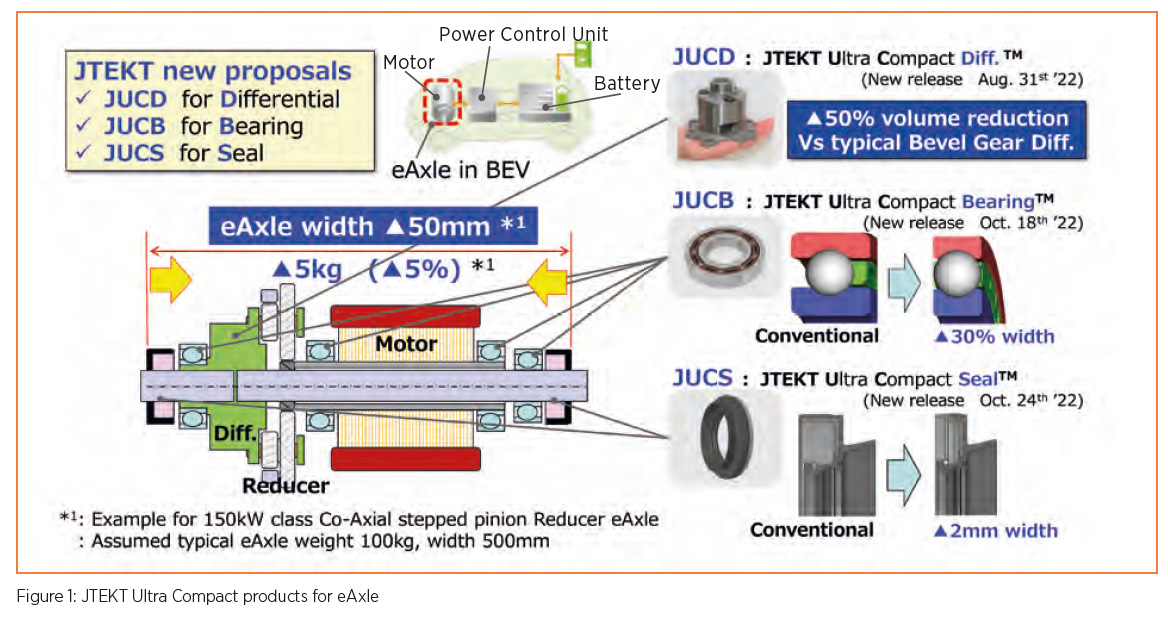

In response to the strong expansion of the battery electric vehicle (BEV) market, JTEKT has developed and just announced “Ultra Compact” product series, JTEKT Ultra Compact BearingTM, JTEKT Ultra Compact SealTM and JTEKT Ultra Compact Diff.TM aiming for e-axle size and weight reduction. (Fig. 1)

“JTEKT Ultra Compact Diff.TM (hereafter referred to as JUCDTM)”, is new differential proposal for BEV e-axle using very unique/patented differential gearing. JUCDTM is extremely small compared with traditional two pinion – one piece housing bevel gear type differential for the same strength.*JTEKT Ultra Compact Diff. and JUCD are registered trademarks of JTEKT.

Needs for eAxle compactness

Following with automotive electrification growth trend and also high ratio of 4 Wheel Drive BEV trend, development and production of eAxle is growing rapidly worldwide. e-axle is the heart of the eDrive system, and integrated inverter, motor, and reducer including differential. In order to develop a better BEV keeping enough battery capacity installation space, the e-axle is required to be smaller and should have much higher lower density (power/weight ratio) in future. In response to this market need, demand of very compact differential for e-axle is expected to grow, and will replace the typical bevel gear type differential widely used for traditional vehicles.

JUCD Background

JTEKT has developed a very compact size and highly durable differential as “JTEKT Ultra Compact Diff.”, which is suitable for BEV e-axle. A differential is a device that absorbs the rotational speed difference between the left and right wheels that occurs in cornering, and transfer the torque between the drive power source to both wheels.

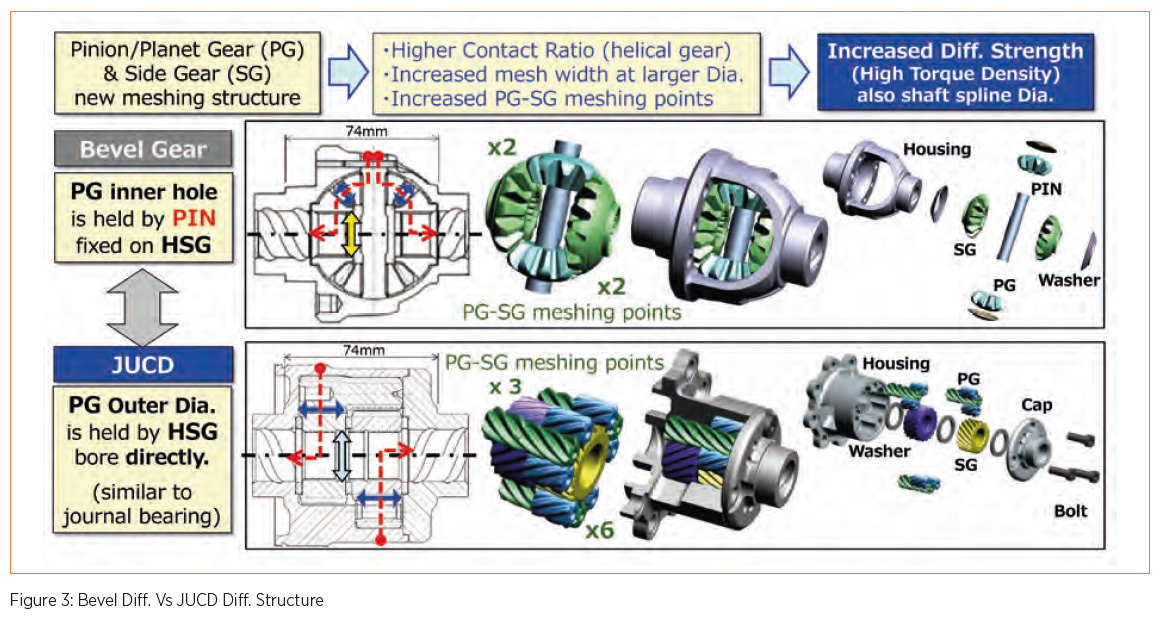

We have further evolved our “No.1 & Only One” product, the Torsen LSD technology, which is a high-performance differential suitable for high power 4WD/sports vehicles, by adding new knowledge of gear design and machining technologies. Introducing smaller gear module geometry into the unique composite planet gear set, we have made it smaller in radial and axial directions, and reborn as “JUCD” general-purpose differential for wide range of eAxles. * LSD: Limited Slip Differential

JUCD Features and Advantages

- High torque density and durability.

- Wide range of torque capacity.

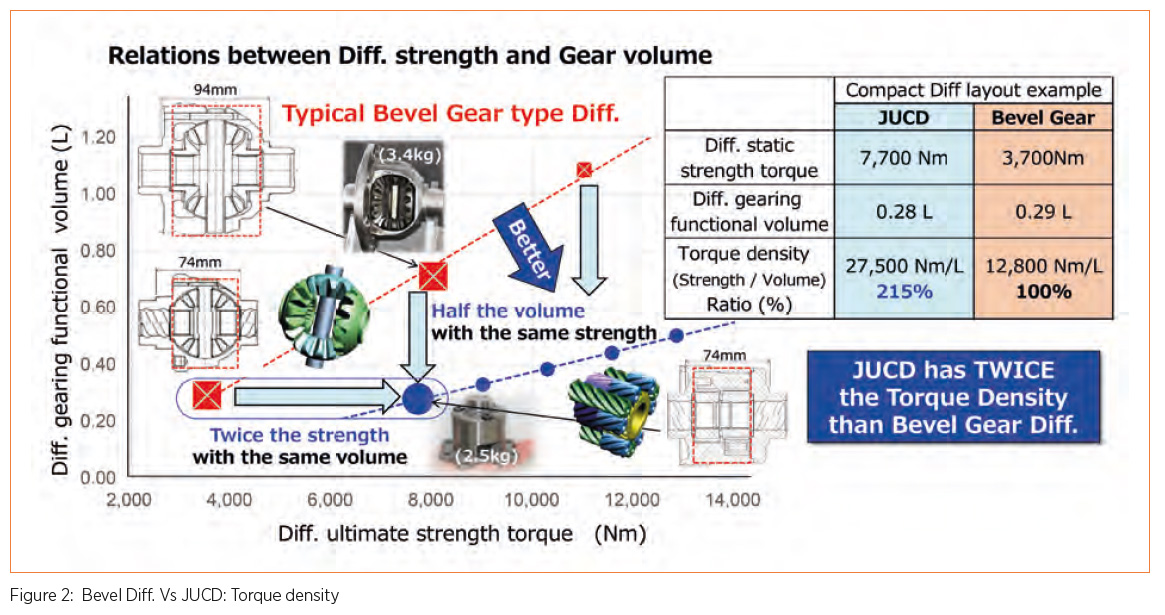

Compared to the bevel gear type differential, JUCD has an increased mesh quantity and wider mesh width at larger diameter between planet gear and side gear. This is possible by using smaller diameter parallel axis planet gears which are directly supported by the housing bore similar with journal bearing structure. (Fig. 3) As a result, for the same differential gearing functional volume, the ultimate strength is more than doubled. Consequently, for the same ultimate strength, the required volume is less than half for JUCD. (Fig. 2)

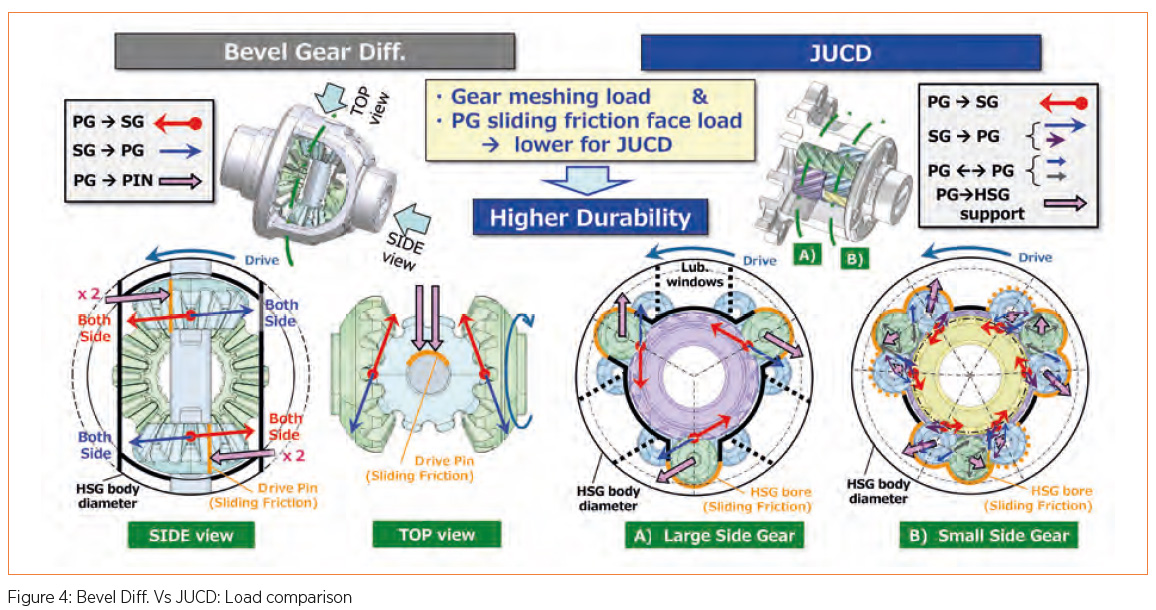

In addition, high durability is ensured by reducing each load of the sliding surfaces between planet gears outside diameter to housing bore, compared with the bevel gear type differential pinion gear hole to drive pin. (Fig. 4)

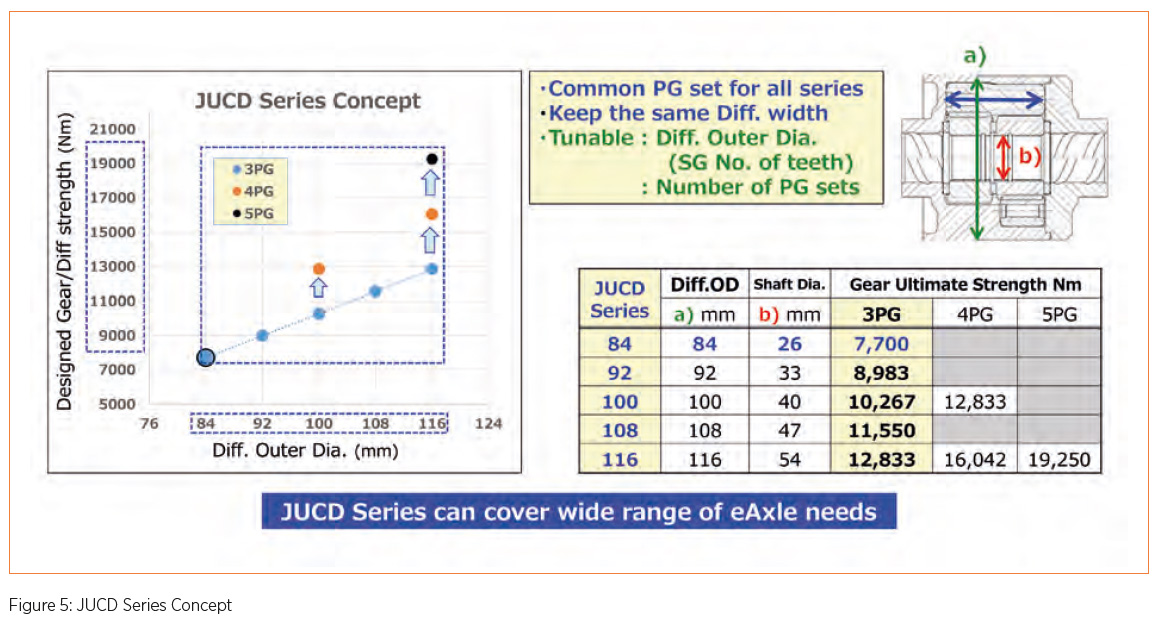

JUCD can support wide range of torque capacity requirement, by selecting the number of side gear teeth and the size of differential outer diameter and/or additional planet gear set, while keeping the common planet gear sets and differential width. (Fig. 5) With these, JTEKT can now propose the optimum ultra compact differential for various eAxle reducer structures and torque requirements. JUCD contributes to the further eAxle compactness and higher power density, and also improves flexibility of the eAxle mountability to the vehicle.

Improve electricity power consumption and safety performance

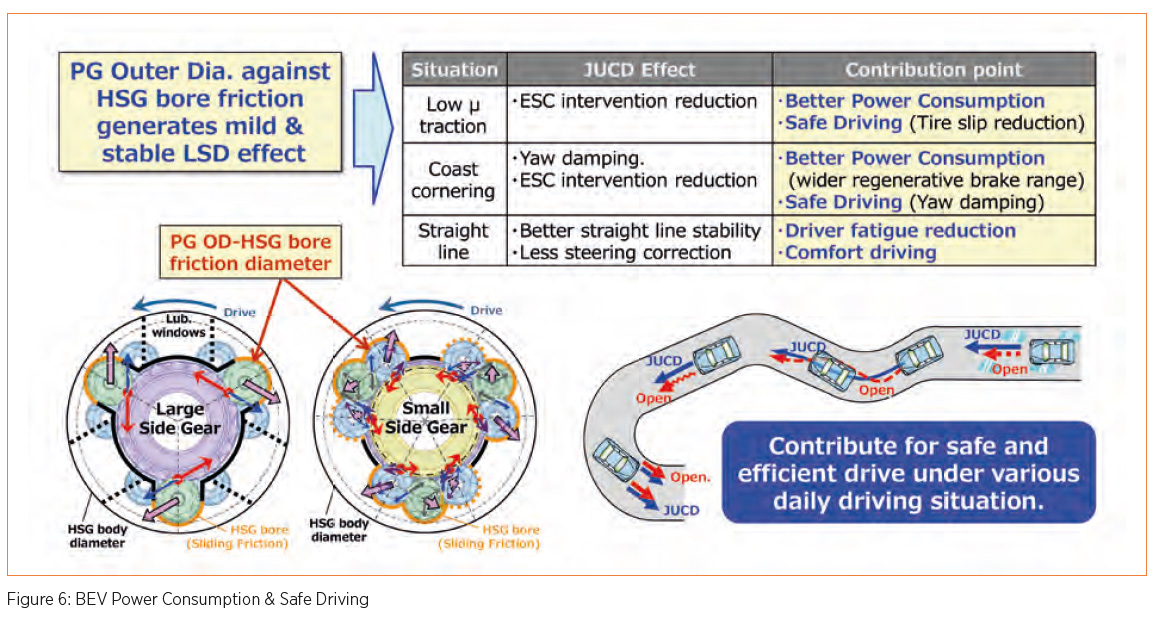

JUCD also has mild and stable torque biasing LSD characteristics derived from its unique structure, mainly by planet gears outside diameter to housing bore friction as journal bearing structure. This feature contributes to reducing the vehicle wheel friction brake load that intervenes when the tire slips at vehicle start on slippery road surface or climbing a hill. It also contributes to expand the range of regenerative braking situations by stabilizing vehicle behavior during deceleration. These effects are expected to improve electricity power consumption. In addition, these characteristics also contribute to improve straight-line stability, which will reduce continuous steering wheel angle adjustment during steady straight-line driving, contributing to reduce driver’s fatigue and improve ride comfort. (Fig. 6)

For more detail

JTEKT Ultra Compact Diff.TM: www.jtekt.co.jp/e/news/2022/220831.html

JTEKT Ultra Compact BearingTM: www.jtekt.co.jp/e/news/2022/221018.html

JTEKT Ultra Compact SealTM: www.jtekt.co.jp/e/news/2022/221024_3.html