ElringKlinger Metalobond is a new full face gluing system for laminated stacks with a high sealing capability to support direct cooling systems in rotors and stators and increase performance.

With increasing rotation speed and less installation space in advance electric engine concepts, heat becomes more and more an issue.

The best way to cope with this issue is to avoid heat generation by reducing electromagnetic losses, e.g. in the iron core. A second approach is to use an efficient direct cooling system to get heat out of the system and therefore increase continues performance of the electric motor significantly.

The first approach drives the sheet metal thickness of the laminated stacks below 0.3 mm. The target is to reduce the eddy current losses in the system and by doing so, reducing the generated heat.

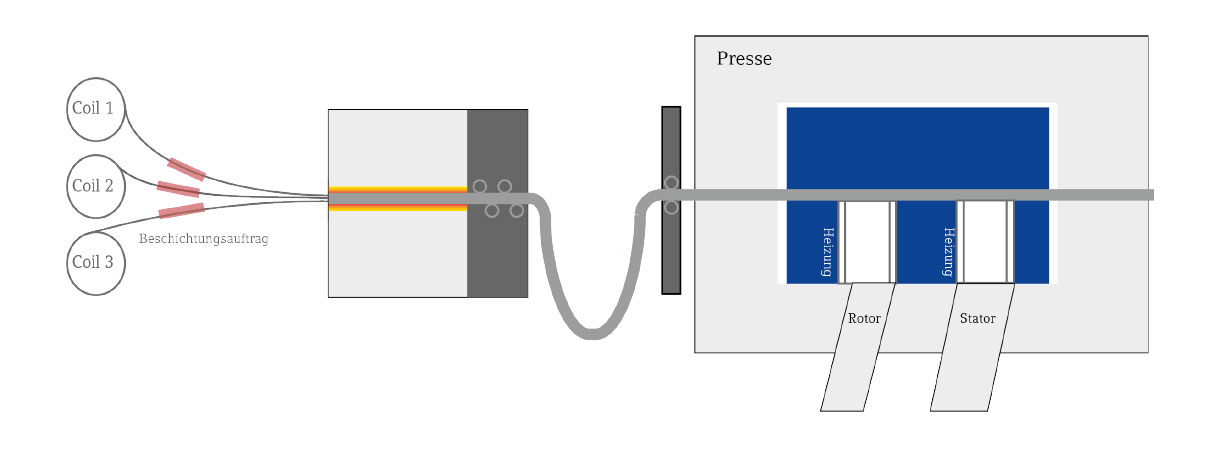

To increase the process efficiency of stamping thin sheet metal layers for laminated stacks, ElringKlinger has developed its multilayerstamping process. Three layers of gluecoated sheet metal are combined to a compound, punched, stacked and full face glued to a form package.

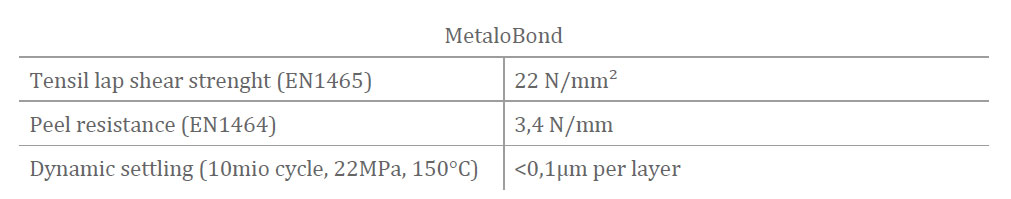

The packages produced in this process with the MetaloBond gluing system achive good values in strength and setting behavoir.

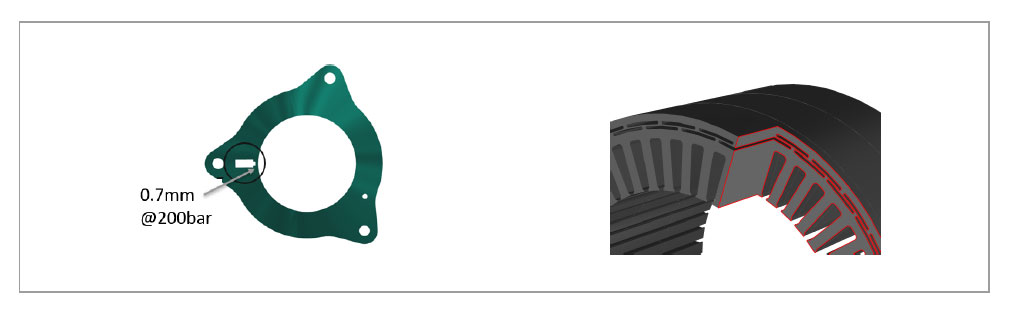

In the second approach, a direct cooling system can be used to remove heat. If the direct cooling system shall be designed within the iron core, a reliable and lifetime durable sealing between the single layers of the iron core must be ensured. With Elringklingers MetaloBond gluing system, this sealing capability is guaranteed. Due to its clear focus on selaing performance it allows a bigger degree of design freedom as other gluing systems on the market. With ElringKlinger MetaloBond, cooling channels can be placed with a distance of only 0.7 mm to the permeter and still seal pressures up to 200bar, even under thermal cycling and thermal shock conditions.

This allows to place cooling channels where they are needed. Either close to the hot spots or close to the perimeter to reduce interruption of magnetic flux. The result is an efficient cooled system with a dramatic increase in continues performance. As a full service supplier, ElringKlinger is able to support you with the full range of services from heat flux calculation, lasered and punched prototypes to fluid flow testing with thermal cycling or shock. If you have further questions or want to discuss your application please visit us at our booth no. A7 at CTI in Novi.

ElringKlinger Contacts

Alexander Heinzelmann

alexander.heinzelmann@elringklinger.com

Fon: +49 (7123) 724 88401

Daniel Roming

daniel.roming@elringklinger.com

Fon: +49 (7123) 724 88114