Magna uses a scalable set of building blocks to create complete powertrain systems for pure electric and hybrid electric vehicles, covering the full range of system architectures from 48 V to 800 V. Cutting edge virtual methods including artificial intelligence algorithms for predicting performance-, efficiency-, durability-, NVH-, thermal- and EMC-attributes are used in an early development phase to functionally integrate the building blocks to an application specific eDrive system meeting the local market and OEM requirements.

Due to large variations in legislation regarding CO2 emission and fleet consumption in the US, Europe and China, many different types of electrified powertrain systems are needed in the market. In addition the end-customer expectations for pure Electric Vehicles (EVs) and Hybrid Electric Vehicles (HEVs) regarding performance and comfort will trigger new requirements on the electric components. It is an excellent opportunity for OEMs to provide a new level of agility and functionality using the additional degrees of freedom provided by Electric Drive (eDrive) solutions.

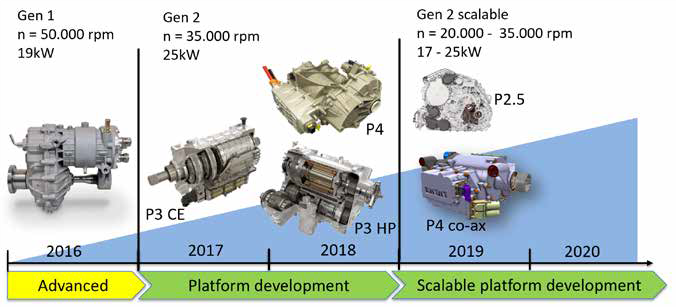

Based on successful eDrive serial products on the market since 2011, Magna developed eDrive platforms with cutting edge technology to meet these high expectations of future automotive applications in the range of 17 kW to 250 kW of power. The so called “building blocks” of an e-motor and inverter are re-used in a wide range of different applications providing flexibility by scaling and improving robustness as well as reducing time to market.

One important platform within this overall product strategy is the 48 V high speed platform, which was developed specifically to cover a forecasted market demand for high volume mild hybrid powertrain systems. Magna’s 48 V e-motor/inverter solutions provide an integration-friendly solution with high recuperation potential as well as the customer benefit of a traction aid system and limited pure electric driving.

Magna’s 48 V serial production platform consists of a scalable permanent magnet synchronous motor (PMSM) to achieve the highest power density and a modular inverter using metal oxide semi-conductor field effect transistors (MOSFETs). These two building blocks are used for several applications with a speed range of 20,000 to 35,000 rpm and a power of 17 to 25 kW peak. This e-motor/inverter platform will be mainly used in applications with very challenging packages in P1, P2.5-, P3- and P4-architectures. There will be an oil cooled version of the motor for the application in hybrid double clutch transmissions. Other applications will use a water-cooled version, and the inverter will be water-cooled in every version. The CO2 benefit of such 25 kW systems can be as much as 21 % depending on the vehicle and system configuration.

platform motor and inverter system is

used for P1, P2.5, P3 and P4 applications

from 17 to 25 kW